WE CREATE INNOVATIVE PROJECTS IN AROMAS AND EXTRACTS

The aromas and extracts industry is a constantly evolving sector, and in recent years, a series of projects have propelled Hausmann Aromatic to a higher level of innovation and growth.

Among others, we have achieved great solutions with our line of natural flavors and extracts for the food sector, using natural raw materials to offer a healthy and sustainable alternative to the artificial additives commonly used in the food industry.

Other successful projects are based on our line of aromas for pharmaceutical and cosmetic products.

At Hausmann Aromatic, we constantly invest in innovative technologies to improve the efficiency of our production processes. We develop advanced extraction and distillation systems that allow us to obtain high-quality extracts and aromas more quickly and efficiently.

All of this has resulted in cost reduction and increased production capacity, achieving a series of successful projects that have propelled the company to new levels of growth.

DISCOVER OUR PROJECTS

PROJECT

DEVELOPMENT OF VANILLIN THROUGH A NEW ENZYMATIC PATHWAY FROM RICE HUSK (ENZIVANIL; file IDI-20210755)

FIELD

Food and Flavor Industry: Industry that directly benefits from the production of vanillin. The demand for natural ingredients is on the rise, particularly with regard to vanillin, which is essential in the flavoring of foods.

DESCRIPTION

- Location: Abrera.

- Budget: 235.920,00€.

- Duration: From October 2021 to September 2023.

- Funding Co-funded by the CDTI and ERDF funds.

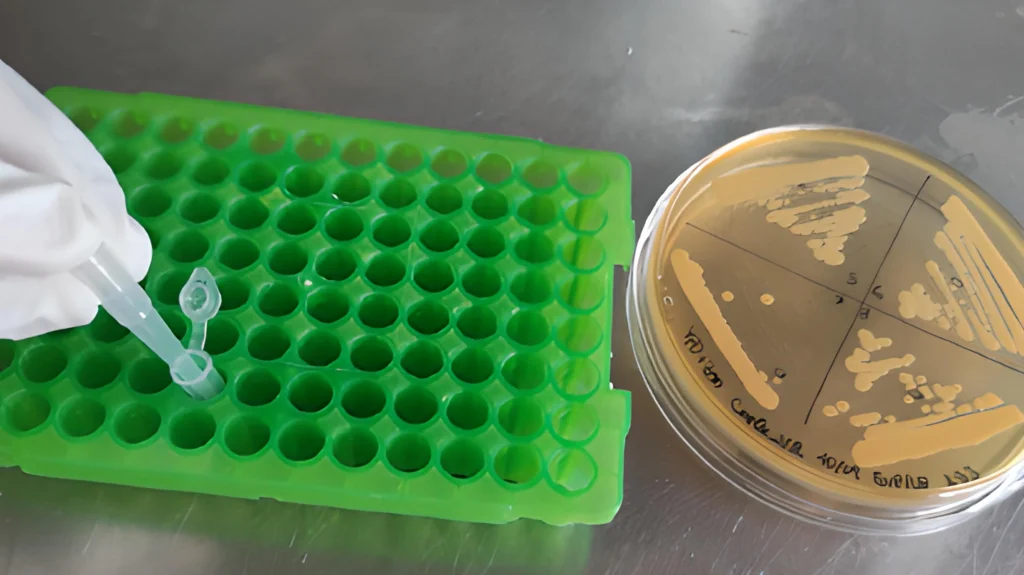

- Process Description: It uses a biotechnological process to convert ferulic acid into vanillin, employing a multi-enzymatic system that does not require costly cofactors, making this method more economical and environmentally friendly.

- ENG4BIO Group from the Autonomous University of Barcelona (UAB) Key collaborators in the research.

OBJECTIVES

- Develop natural vanillin that can be classified as such according to the regulations of the European Union and the United States.

- Production optimization through the use of specific enzymes and a multi-enzymatic system.

- Reduction of environmental impact associated with traditional methods of vanillin production, including reducing the need for cofactors and simplifying purification processes.

PROJECT

DECARBOFARM

FIELD

Agricultural and Agri-food Technology: The project directly benefits this sector, focusing on improving the sustainability and resilience of agricultural practices in response to climate change.

DESCRIPTION

- Budget: More than 1.5 million euros, with over one million euros funded by CDTI.

- Duration and Funding Part of the 'Missions Science and Innovation' program organized by CDTI. It is one of the 42 projects selected out of 137 submissions

- Description: The project involves the development of new bioactive products for use in fertilizers, employing sustainable production systems that incorporate beneficial microorganisms and stress-adapted rootstocks. The aim is to reduce greenhouse gas emissions and improve the efficiency and health benefits of cultivated plants.

- Paudire y FGT i associats: R&D funding consultants from Murcia and Catalonia, respectively, responsible for project management and documentation.

- Sicop y Unigenia: Part of the consortium, providing technological solutions

- CEBAS-CSIC: Collaborative research entity, providing scientific support through Professors José Antonio Pascual, Micaela Carvajal, and Francisco Pérez.

OBJECTIVES

- Increase sustainability and resilience of tomato cultivation as a model plant to contribute to climate change mitigation and adaptation.

- Develop bioactive products that increase photosynthesis and CO2 fixation, improving crop growth, resource efficiency, and environmental tolerance.

- Produce healthier and more efficient vegetables With fewer chemical contaminants, aligning with the European Commission's 'Farm to Fork' strategy.

- Establish the consortium as a national and global leader in the research of bioactive products for fertilizer improvement.